With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces sheet metal is one of the very convenient ways that is used in metal working and it can be mended and cut into various shapes and dimensions.

Fundamentals on the miniaturization of sheet metal working processes.

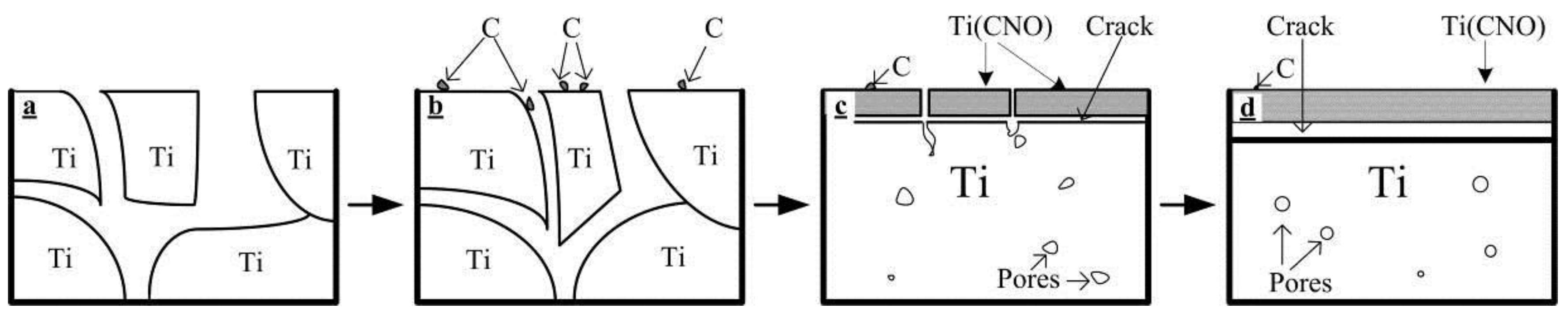

As a result so called second order size effects occur.

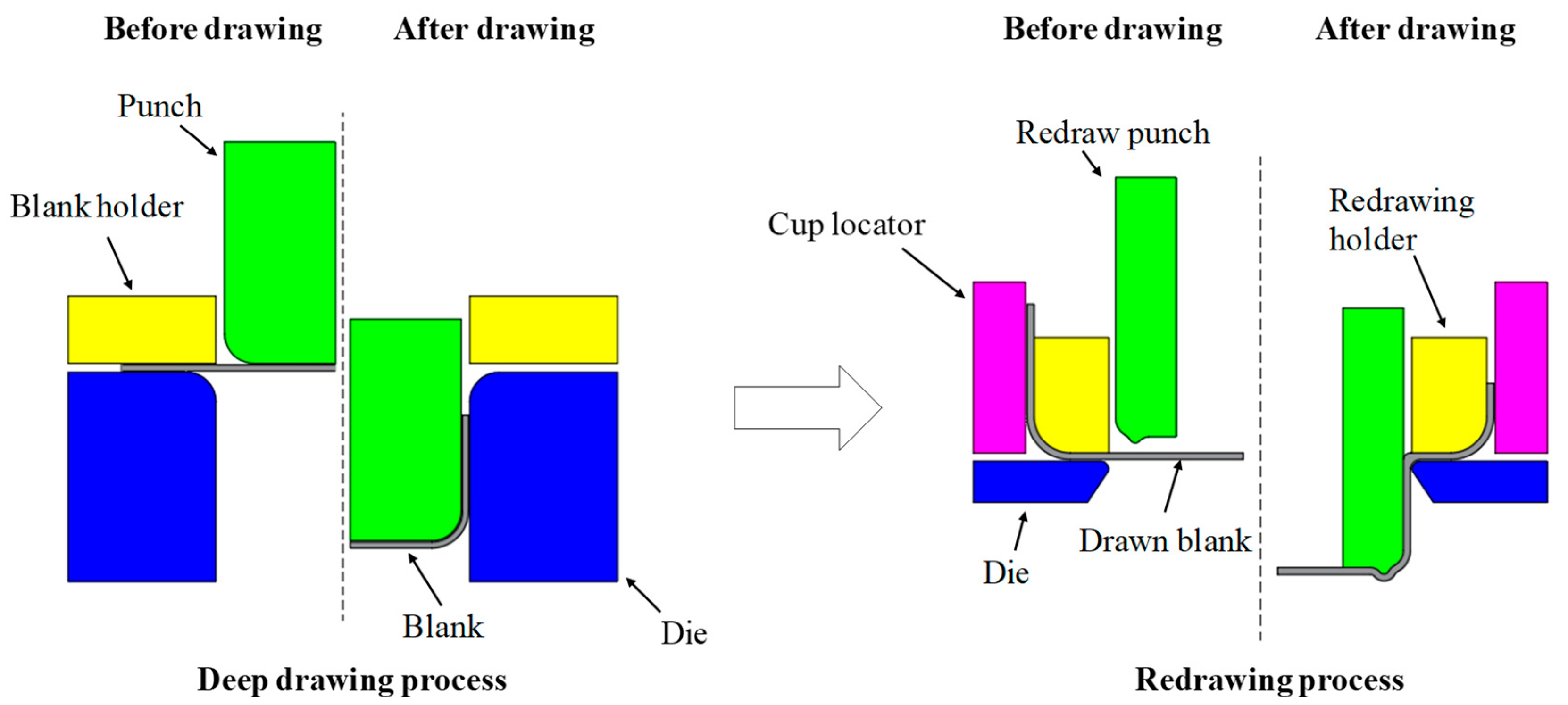

Miniaturization of sheet metal working processes causes changes in the relative contribution of relevant process parameters.

16 kalpakjian design for sheetmetal working ch.

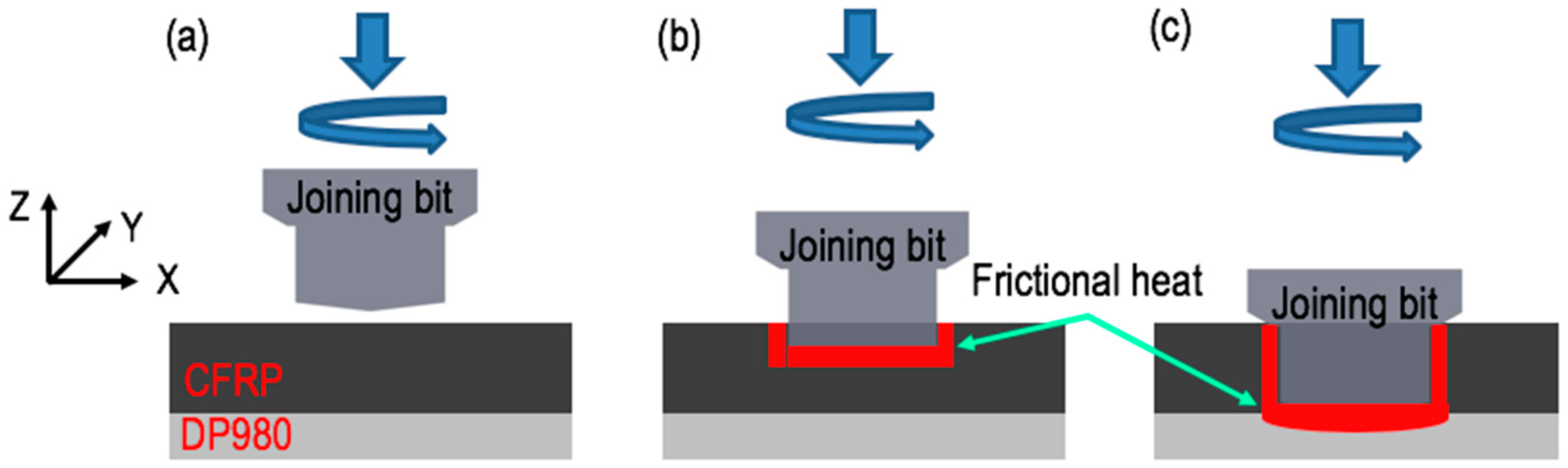

A further material phenomenon which occurs in sheet metal working processes is the influence of the sheet anisotropy on the process.

Sheet metal work stock used for sheet metal processes is usually formed by rolling and comes in coils.

Such basic features can be summarized as.

9 boothroyd dewhurst and knight.

Sheet metal forming basics.

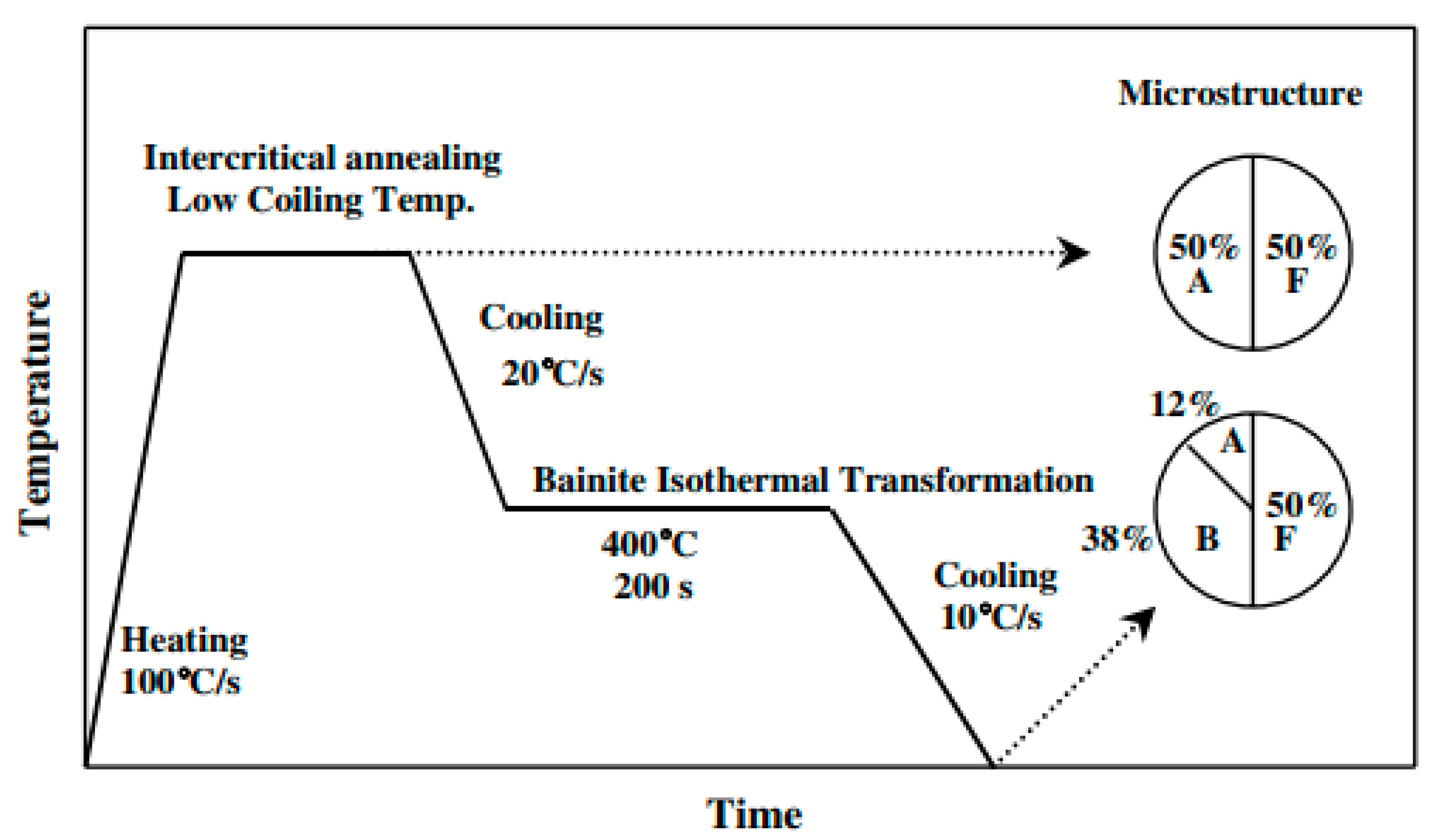

Groover fundamentals of modern manufacturing 2 e strain rate sensitivity theoretically a metal in hot working behaves like a perfectly plastic material with strain hardening exponent n 0 the metal should continue to flow at the same flow stress once that stress is reached.

The simplified die addendum.

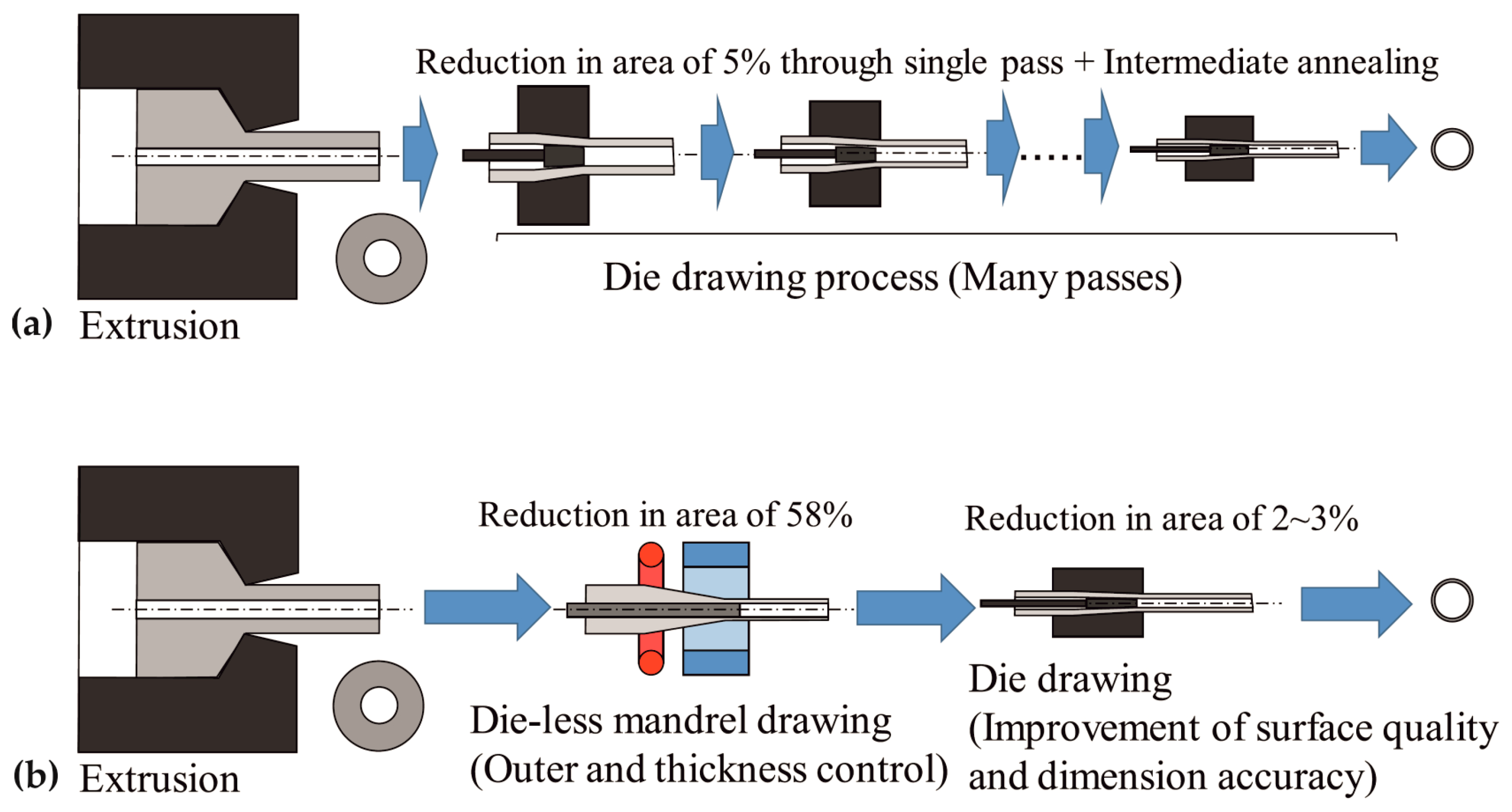

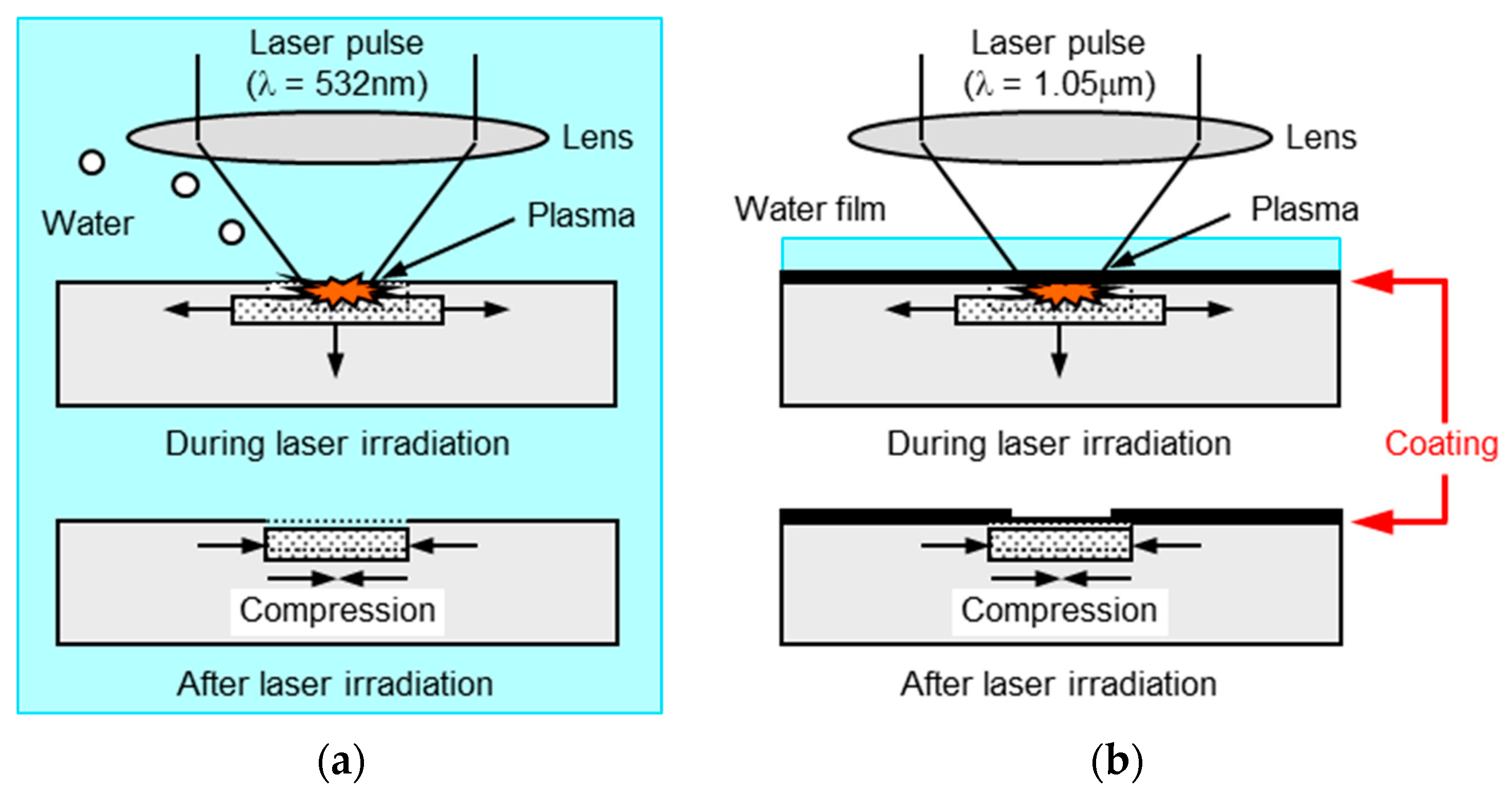

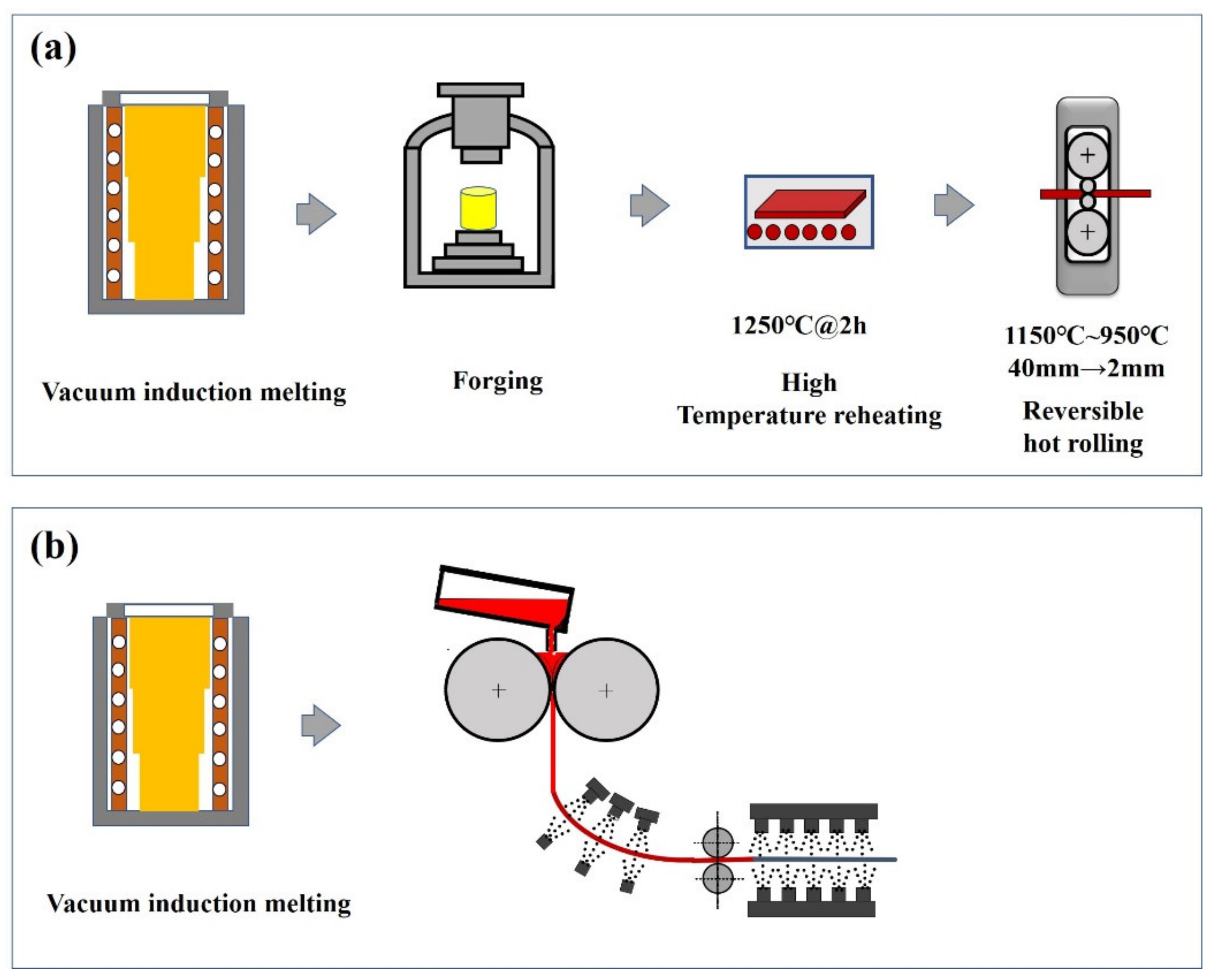

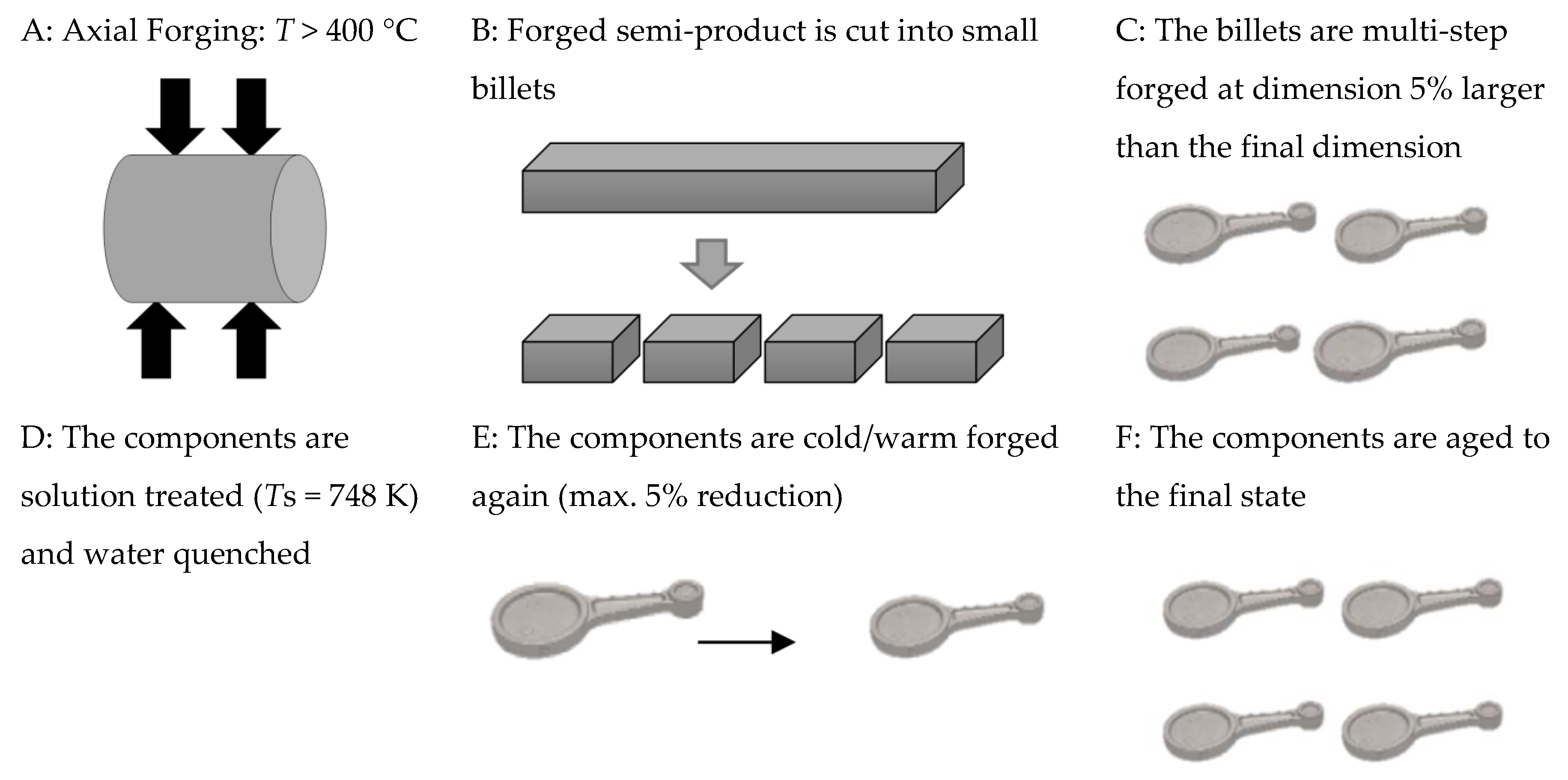

Ongoing miniaturization in various technical fields such as the electronics industry or micro systems technology requires precise forming processes for the production of small and thin components.

2002 john wiley sons inc.

The process of folding is employed at the.

The effect of the anisotropy in micro sheet metal blanking processes has been investigated in connection with the production of lead frames.

The hinges that connect doors to walls and cabinets consist of sheet metal which is cut to shape and punched with holes that are fitted to fasteners.

They contain long and narrow slots made by blanking which means that.

For example thin metal foils are being used in microelectromechanical systems electronic components and medical devices.

Miniaturization of sheet metal working processes causes changes in the relative contribution of relevant process parameters.

Sheet metal forming involves a wide range of processes that manufacture parts for a vast amount of purposes both seen and unseen.

Sheet metal forming 2 810 d.

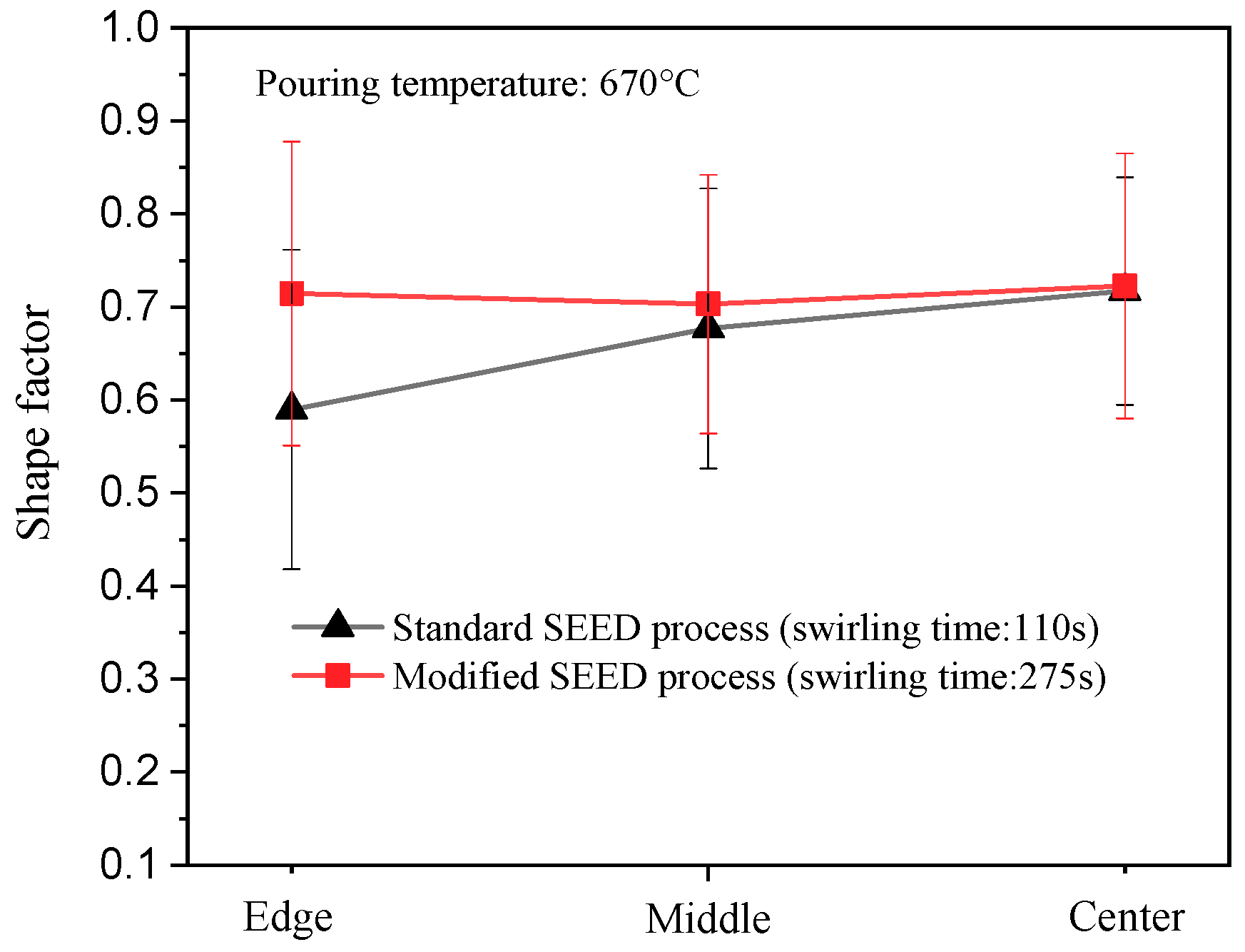

The present paper should give a survey of different kinds of second order size effects that can be expected in tensile testing air bending and punching of sheet metal.

Sheet metal refers to metal that has a high surface area to volume ratio.

Cooper sheet metal forming ch.

Basic geometry feature of the dieface although an actual dieface is a rather complicated system of surfaces some basic geometry features can be identified.